- No.361, SIDCO Industrial Estate, Ambattur, Chennai - 600 098.

- (+91) 95009 79331 srinivasin62@gmail.com

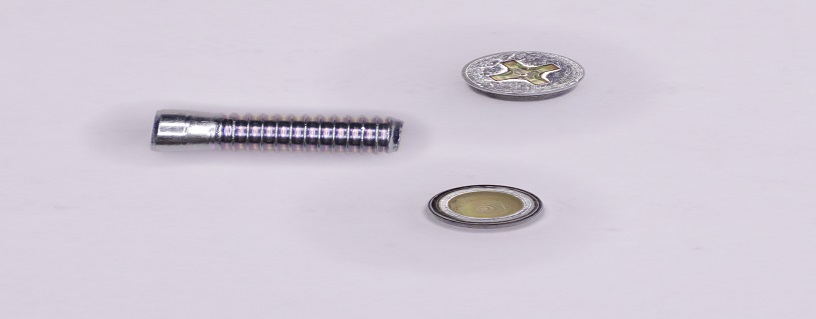

Drive: The shape of the head, which dictates the type of tool needed (e.g., Phillips, slotted, Torx). How Screws Work: Screws work by converting rotational force (torque) into linear force, allowing them to penetrate and grip materials. The threads create friction, which resists withdrawal. Common Applications: Joining Materials: Screws are used to fasten wood, metal, plastic, and other materials together in construction, manufacturing, and various DIY projects. Adjusting and Positioning: Screws can be used to adjust the position of components or to clamp objects together. Creating Motion: In some cases, screws are used as part of mechanisms to create linear motion (e.g., ball screws in machinery).

There is a wide variety of screws, each designed for specific applications: Wood Screws: Designed for use in wood, often with a sharp point and coarse threads. Machine Screws: Used for metal and often require a pre-tapped hole. Drywall Screws: Designed for attaching drywall to studs. Self-Tapping Screws: Can cut their own threads as they are driven into the material. Sheet Metal Screws: Similar to self-tapping screws but often have a sharper point for use with sheet metal. Lag Screws: Large screws with a hexagonal head, often used for heavy-duty applications. Ball Screws: Used in precision applications to convert rotary motion to linear motion.

Joining Materials: Screws are used to fasten wood, metal, plastic, and other materials together in construction, manufacturing, and various DIY projects.